Quality Traceability

667,000

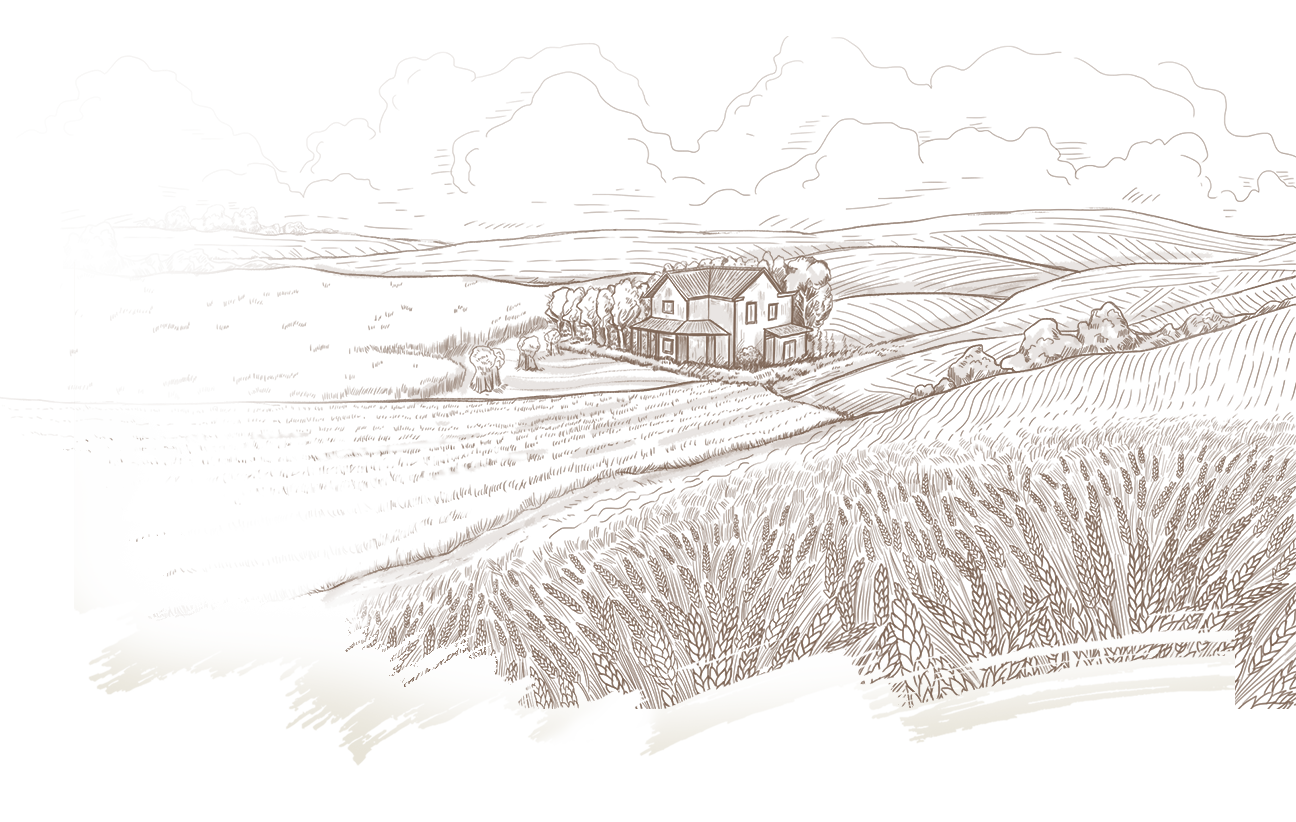

Square metersIn order to fully ensure food safety and improve the level of wheat planting, Braisun invested heavily to build a 667000 square meters demonstration planting base of high-quality wheat varieties on the Yellow River Beach in 2010. The base cooperates with "Dishen" Seeds Co., Ltd., the most well-known wheat research institution in China,and introduces all the highest quality wheat varieties. During the whole process, the pure natural green planting methods are adopted without using any chemical fertilizers and pesticides. In that year, the Baixiang High-quality Wheat Demonstration Base achieved a gratifying result that the yield per mu exceeded 600 kilograms, which not only met the self-sufficiency needs of the Baixiang Food Group for high-quality flour, but also explored a scientific path for the cultivation of high-quality wheat in the surrounding cities of the base.

More+